What is Hydroforming?

Hydroforming, otherwise known as the SAAB fluid forming method or simply Fluidforming, was developed in the 1950’s as an extension of the rubber pad forming method (referred to under such names as Guerin, Verson,Wheelon, Marform methods). Both methods were developed for industries with low volumes and high varieties of relatively thin gauge sheet metal formed parts,such as in the production of aircraft components. And again both methods were similar in that they had the advantages of low tooling (and tooling proving) costs and, due to their inherently better control of metal movement, permitted more “severe” forming than conventional tools thereby also enabling more complex shapes to be produced whilst maintaining finished part integrity.

Both methods reduce the degree of marking which can occur with conventional forming methods and, as it is a “smooth” forming process they eliminate any cracking and wrinkling. Hydroforming has the advantage over rubber pad forming in forming pressures (up to 20,000 psi) can be achieved allowing stronger materials to be formed e.g. high strength alloys of aluminium, nickel alloys and titaniums.

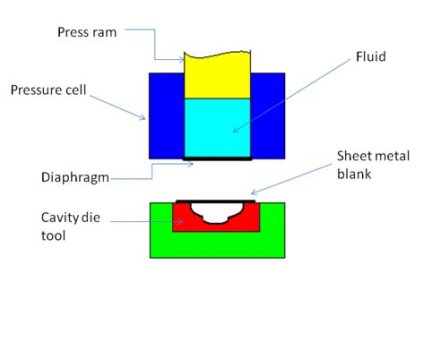

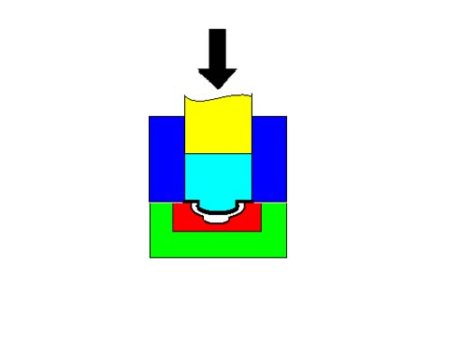

In basic terms the principle in both rubber pad forming and Hydroforming is that one half of the conventional solid, hard metal punch and die forming set is replaced by one half of the tool being made from a flexible “tool” and the other half, either the die cavity or the punch,remaining solid. With Hydroforming this flexible half is an oil filled fluid cell as opposed to a rubber block or pad. This fluid cell is made up of a steel cylinder, a fluid chamber and a rubber, or urethane, diaphragm. There are two methods employed to pressurise the fluid i.e. in the case of a self-contained unit the oil is pressurised by the action of the ram of the hydraulic press machine on the telescopic cylinder which, acting through the hydraulic oil, exerts pressure on the diaphragm; these self-contained units are commonly referred to as being SAAB units. Alternatively special purpose Fluid cell presses have an integral fluid cell which is mounted on a stationary ram whereby pressure is exerted on the diaphragm via the machine’s hydraulic pumps pumping high pressure hydraulic oil directly in to the fluid chamber.

Advantages of using SAAB self-contained units are that they can be moved around and attached to anyone of a number of different hydraulic presses, or can be removed completely to allow the press to be used in a conventional way. Whereas a purpose built dedicated machine is quicker to set up, can have an infinitely programmable pressure range (up to the maximum rating) which is easier to control, and it is often quicker to operate. In both cases the diaphragm enables the pressure to be exerted evenly around the whole of the component blank throughout the forming process and the metal is formed into the cavity or around the punch. This smooth forming process eliminates cracking and wrinkling whilst containing material thinning to a minimum if not none at all. It is typically suitable for sheet metal gauges up to 4swg/6mm.

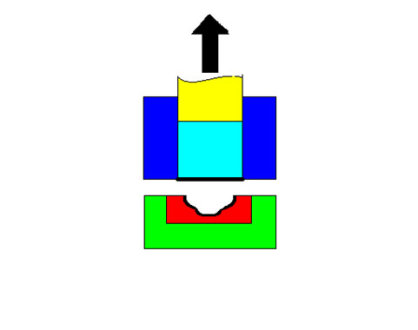

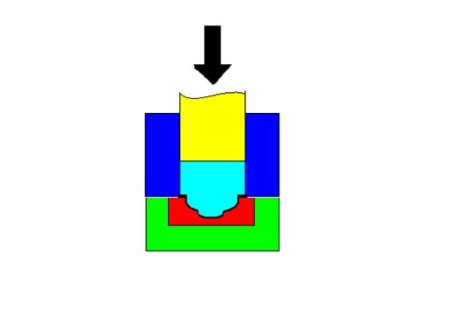

The following diagrams show the SAAB method and help to illustrate the process. Note that the dedicated press’ integral unit follows the same principle but the ram is replaced by a hydraulic pump system which directly energises the pressure cell.

Stage 1 – blank in position across tool

Stage 3 – ram continues to push down until desired pressure is reached

Stage 2 – pressure cell in position, ram pushes down & forming begins

Stage 4 – forming cycle is complete and unit is withdrawn leaving finished part