leading experts in aerospace welding

MSM aerospace fabricators has a team of highly skilled and experience welders.

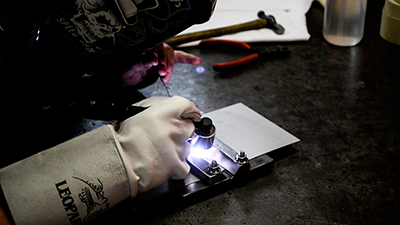

MSM’s highly skilled and experienced laser welding team is NADCAP approved across the full range of aerospace welding and laser welding processes. Our aerospace welders and laser welders are widely recognised as being in the top echelon of the industry. TiG welding and brazing of all aircraft materials by hand is complemented by Hobart and Jetline auotmated welding for greater control and reduced cost.

MSM has one of the largest resistance welding facilities in the UK, enabling spot and seam welding of aluminium, stainless steels, inconel 625, inconel 718 and titanium. Applications for this facility include engine jet pipes, intakes, manifolds and fireskins and also aircraft structure and control surface spot weld assemblies.

If you have a requirement for aerospace welding and fabrication, then please contact MSM aerospace fabricators who’d be pleased to provide you with a technical proposal and a competitive quote. More information on MSM’s other specialist NADCAP approved processes is on our website.