specialised in assembling high precision, complex, aircraft sheet metal assemblies

MSM aerospace fabricator’s is made up of highly skilled, aerospace trained sheet metalworkers.

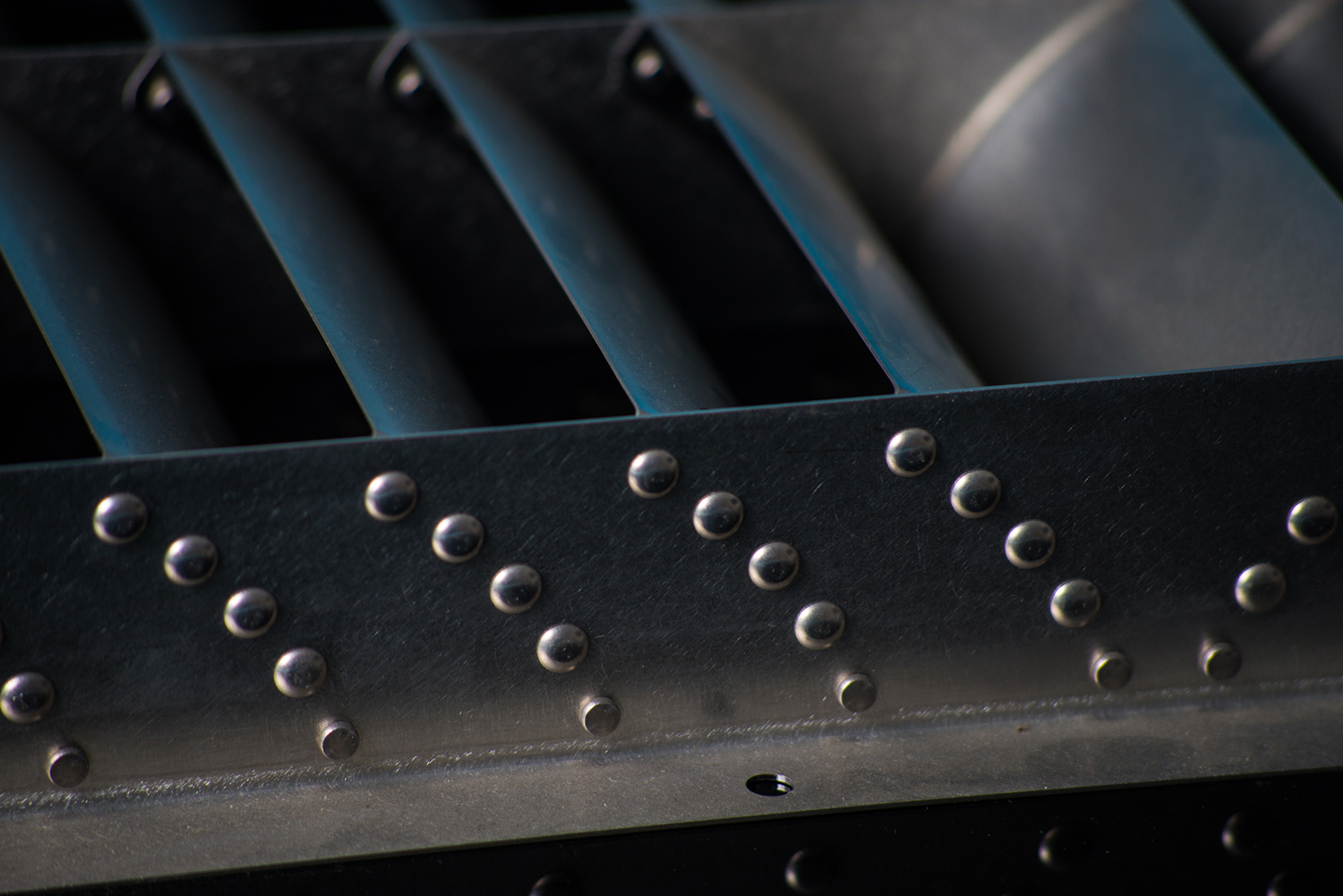

MSM’s highly skilled, aerospace trained sheet metalworkers and fitters are specialised in assembling high precision, complex, aircraft sheet metal assemblies such as air intakes, exhaust nozzle sub-assemblies, piccolo tubes, jet pipes, bleed air duct assemblies and exhaust louvres. Every member of the team is trained in human factors and is focussed on safety, quality, precision and efficiency.

A wide range of skills are deployed including hydraulic riveting, metallic insulation lagging, manual tack welding, bonding, pressure testing and the development of sheet metal profiles. MSM specialises in using high temperature resistant materials such as titanium and nickel alloys.

MSM covers the complete range from one-off R & D development assemblies through to fully optimised Lean assembly cells for larger quantities.

If you need more information or you would like to discuss a specific requirement please contact a member of the MSM team.