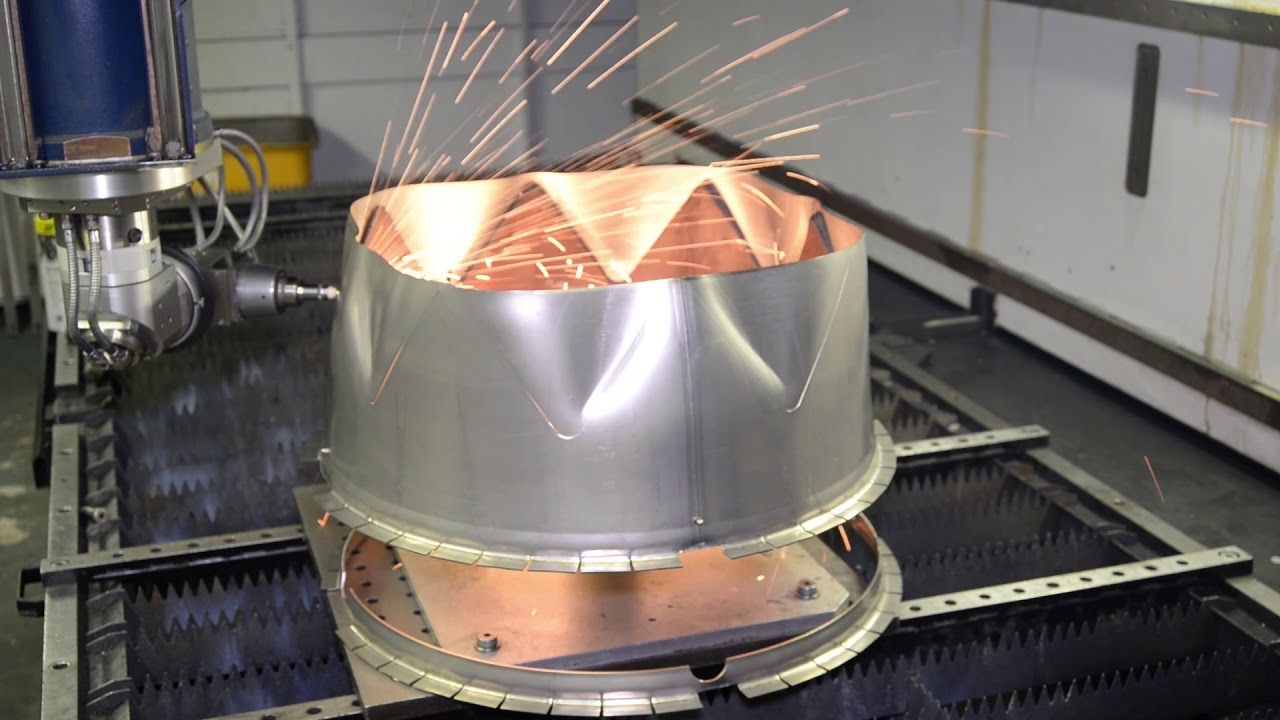

5 axis laser cutting & welding

MSM’s NADCAP approved laser cutting and laser welding facility includes the newest 5 axis TRUMPF 7040 LASER.

This machine utilises the very latest in “state of the art” industrial laser technology. Incorporated into a large working capacity and highly efficient production centre the TRUMPF 7040 is ideally suited to laser cutting and laser welding high strength, heat resistant metals as used in the aerospace and other high technology industries.

A key feature of the machine is the fact that the solid state laser beam is guided through fiber cable making it more accurate, more consistent, faster and more efficient than the CO2 equivalent. Having interchangeable quick change heads it can perform high speed (up to 40m/min),high precision (<0.1mm positional and < 0.03mm repeatability) and high efficiency laser cutting and laser welding of the most complex 3D components.

5 Axis Laser Features:

Working capacity of 4m x 2m x 2m

High speed up to 40m/min

Increased solid-state laser beam accuracy through fiber cable guidance

Minimises need for cleaning

Small molten materials and short melting point allow dis-similar materials to be combined

Minimal distortion

Typical HAZ of below 0.01mm

High precision up to <0.1mm positional and <0.03mm repeatability

Reduced time when compared to manual methods

High accuracy and small kerf means reduced material waste

If you need more information or you would like to discuss a specific requirement please contact a member of the MSM team.