MSM invests in VTL

MSM has invested in a VTL and state-of-the-art auto-Tig welding equipment to increase our efficiency and capabilities. Both machines will allow higher rate and improved abilities through our roll and weld cell.

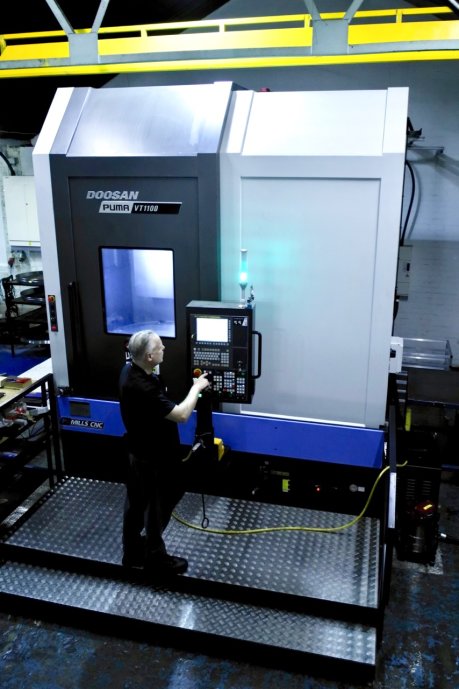

The latest addition to MSM’s capability, the Doosan 1100 VTL was purchased from Mills CNC to supplement our roll and weld cell, and to add value in the manufacture of aircraft engine and exhaust rings.

The vertical lathe was purchased, installed (including building works) and commissioned in a short time frame, and is now in production with components for the A320 neo programme.

MSM forms sheet metal components within a 1m diameter envelope and the Doosan allows us to finish machine the fabricated parts to tight tolerances, increasing the offering to our customers. It also takes MSM to another level in scope with machined fabrications, a niche area in the aerospace supply chain.